Thanks to advanced engineering with Finite Elements Modeling the implementation IsoFrame Technology brings highest possible compatibility with diagnostics – specially in MRi environment. Optimized implant’s construct resulted significant reduction of metal volume, while keeping high durability. Due to IsoFrame also optimal balance between metal volume and endplate contact area has been achieved.

Improved diagnostic properties – anatomical structures are better visible in MRI environment due to reduced levels of metal interference (artifacts).

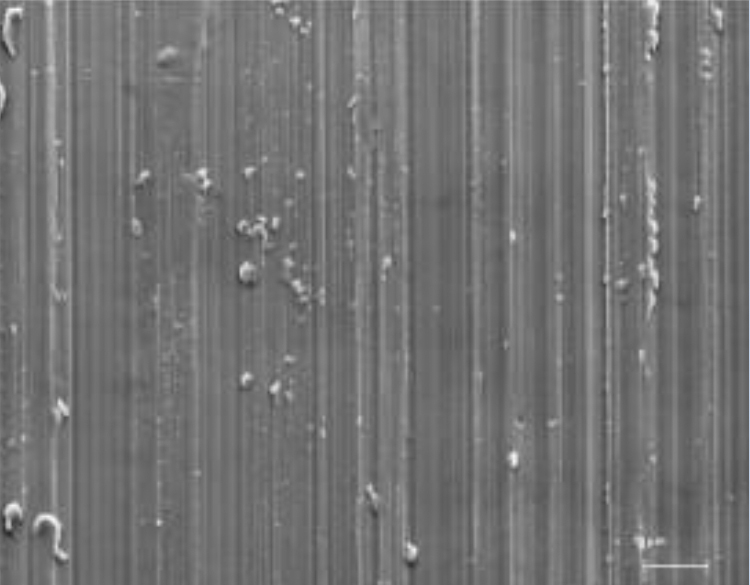

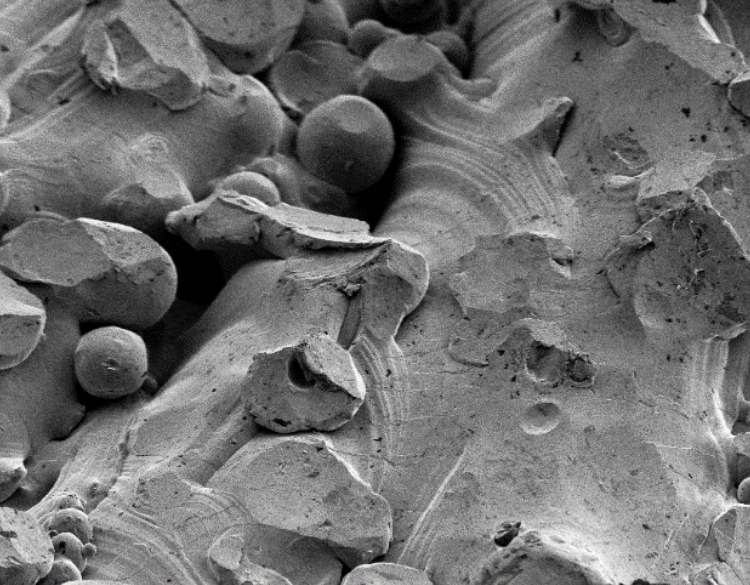

Thanks to additive manufacturing, effective contact surface is increased approximately 5 times – comparing to classical CNC machining.

New bone structures growth process Is accelerated by engaging Wolf’s law

DCS employs controlled subsiding process and by following the cellular mechanism of bone remodeling initiates bone cells reversal process.

Engaging Wol’s Law accelerates process of new bone scaffolds growth.

Titanium creates direct interaction between an implant and bone – the process is called osseointegration.

Additive Manufacturing gives great possibility to control and precise engineer implant surface. The porous properties of titanium surface contributes to extensive bone infiltration, allowing osteoblast activity to take place (osteointegration). The porous structure allows also soft tissue adherence and vascularization within the implant.

1 Mechanical Signaling for Bone Modeling and Remodeling. Alexander G. Robling and Charles H. Turner, Crit Rev Eukaryot Gene Expr. 2009 ; 19(4): 319–338)

We are a privately held spine interbody implant and surface technology company. Our team members with rich experience more than 25 years in spine have seen over 10 000 spine surgeries and had several hundreds of hours of discussions with you – spine surgeons – to obtain much appreciated feedback on how to treat patients with spine disorders most successfully.

Several hundreds of hours of discussions with spine surgeons created a solid connection between spinal biomechanics and cutting edge technologies implemented into innovative products.

If you have any questions about our products or the technologies we use feel free to contact us via the contact form.

If you are interested in becoming our business partner see more information here.